Industry News

current location: home > news > Industry News

current location: home > news > Industry News

Release time:2024-11-01

Release time:2024-11-01 Number of views:

Number of views: In the field of industrial production, effective conversion and utilization of energy are key factors in improving production efficiency, reducing costs, and minimizing environmental impact. As an important equipment for converting fuel energy into thermal energy, the design, operation, and maintenance of industrial combustion systems are crucial for the efficiency and safety of the entire production process. A deep understanding of the components of industrial combustion systems can help us better optimize energy use, improve combustion efficiency, and ensure the safety and environmental friendliness of the production process. This article will explore in detail the components of industrial combustion systems, in order to provide valuable references and insights.

What are the components of an industrial combustion system

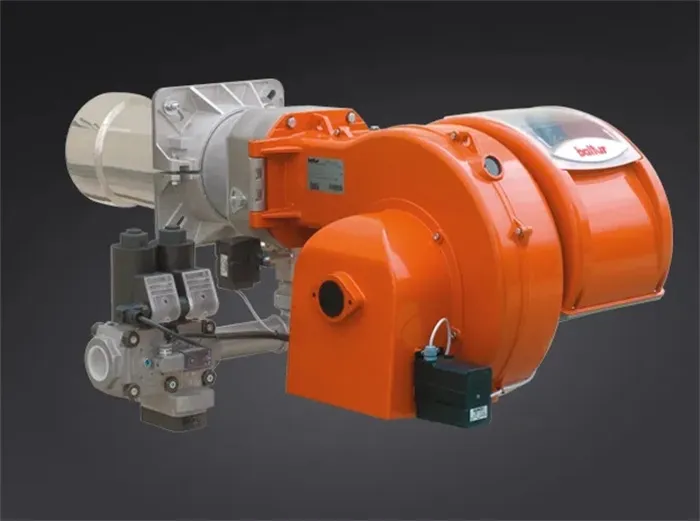

1. Burner

The burner is the core component of industrial combustion systems, which mixes fuel with air and ignites it to generate the required heat energy. The design of the burner must ensure sufficient combustion of the fuel to improve thermal efficiency and reduce harmful emissions. Modern burners are typically equipped with advanced control systems that can automatically adjust the supply of fuel and air based on load changes to maintain good combustion conditions.

There are various types of burners, including gas burners, liquid burners, and dual fuel burners, which are designed according to different fuel types and combustion requirements. The key components of the burner include the nozzle, combustion head, and ignition device. The nozzle is responsible for spraying fuel in an appropriate atomization form for mixing with air; The combustion head is responsible for forming a stable combustion zone; The ignition device is used to ignite a mixture of fuel and air.

2. Fuel supply system

The fuel supply system is responsible for transporting fuel from the storage point to the burner. The design of this system will vary for different types of fuels, such as natural gas, liquefied petroleum gas, or kerosene. It usually includes fuel storage tanks, conveying pipelines, valves, and metering equipment. In order to ensure the continuity and safety of fuel supply, this system also needs to be equipped with necessary safety devices, such as leak detectors and emergency shut-off valves.

3. Air supply system

A large amount of air is required during the combustion process to support complete combustion of the fuel. The air supply system includes blowers, air filters, and regulating valves, which work together to provide the required air flow. Air filters are used to remove impurities from the air to protect the burner and improve combustion efficiency. The regulating valve is used to adjust the air flow according to the combustion demand.

4. Control system

The stability and efficiency of industrial combustion systems largely depend on their control systems. The control system monitors the combustion process through various sensors, such as flame temperature, pressure, and oxygen content, and adjusts the supply of fuel and air based on this data. In addition, the control system also includes an emergency stop function to address potential safety issues.

5. Ignition system

The ignition system is the key to initiating the combustion process. It usually includes an ignition transformer, ignition electrode, and ignition controller. The ignition system must be able to reliably ignite the mixture of fuel and air under various environmental conditions to ensure the smooth progress of the combustion process.

6. Smoke exhaust system

The exhaust gas generated by combustion needs to be discharged through the smoke exhaust system. This system includes a flue, chimney, and exhaust fan, which work together to ensure the smooth discharge of exhaust gas. The design of the smoke exhaust system must take into account the temperature, pressure, and composition of the exhaust gas to ensure its safe and effective operation.

7. Heat exchanger

A heat exchanger is a device used in industrial combustion systems to transfer thermal energy. It is usually located at the outlet of the burner, transferring the heat generated by combustion to the medium that needs to be heated, such as water in a boiler. The design and material selection of heat exchangers are crucial for improving thermal efficiency and extending equipment life.

8. Safety device

Safety is the primary consideration in the design of industrial combustion systems. Safety devices include flame monitors, pressure switches, temperature sensors, etc., which are used to monitor the combustion process and ensure that it operates within a safe range. When abnormal situations are detected, these devices can automatically cut off fuel supply to prevent accidents from occurring.

9. Auxiliary equipment

Auxiliary equipment includes fuel filters, valves, pipelines, and insulation materials, which support the stable operation of the combustion system. Fuel filters are used to remove impurities from fuel, valves are used to control the flow of fuel and air, and pipelines and insulation materials are used to transport fuel and air while reducing heat loss.

As a key link in energy conversion in industrial production, through in-depth analysis of the components of the industrial combustion system, we can see that the system is mainly composed of burners, fuel supply systems, air supply systems, control systems, ignition systems, exhaust systems, heat exchangers, safety devices, auxiliary equipment, and emission control systems. These components work together to ensure efficient combustion of fuel, while controlling pollutant emissions, improving energy efficiency, and ensuring production safety and environmental protection.

Electronic mailbox:

Electronic mailbox:

807600036@qq.com

Looking forward to your contact! scan

scan